PHARMACEUTICAL QUALITY SYSTEM

Objective:

- Achieve product realization

- Establish and maintain a state of control

- Facilitate continual improvement

ICH-Q10: PHARMACEUTICAL QUALITY SYSTEM

The pharmaceutical quality system “assures that the desired product quality is routinely met, suitable process performance is achieved, the set of controls are appropriate, improvement opportunities are identified and evaluated, and the body of knowledge is continually expanded

PQS – IMPLEMENTATION

Quality System Element are described in Quality Manual

Quality, safety and Effectiveness must be designed and built into the product. Quality cannot be tested into the product.

Product Quality depend on:

Each step in manufacturing process must be controlled to maximize the probability that finished product will meet all its quality and design specification

GMP GUIDANCE / REFERENCE - FDA

FDA-CFR Part 211

Sec. 211.100 Written procedures; deviations

There shall be written procedures for production and process control designed to assure that the drug products have the identity, strength, quality, and purity they purport or are represented to possess. Such procedures shall include all requirements in this subpart. These written procedures, including any changes, shall be drafted, reviewed, and approved by the appropriate organizational units and reviewed and approved by the quality control unit.

Written production and process control procedures shall be followed in the execution of the various production and process control functions and shall be documented at the time of performance. Any deviation from the written procedures shall be recorded and justified.

FDA - EXPECTATION

- The deviation must documented. That event should be led by the Quality Unit and conducted with the laboratory or operational department in a collaborative approach that provides subject expertise as well as objectivity

- The FDA will record failures to conduct thorough and timely deviation investigations, and if a pattern of failures is documented

GMP GUIDANCE / REFERENCE – PIC/S

PIC/S PE 009-14

Pharmaceutical Quality System

The results of product and processes monitoring are taken into account in batch release, in the investigation of deviations, and, with a view to taking preventive action to avoid potential deviations occurring in the future

An appropriate level of root cause analysis should be applied during the investigation of deviations, suspected product defects and other problems

GMP Practise for Medical Product

Any significant deviations are fully recorded, investigated with the objective of determining

the root cause and appropriate corrective and preventive action implemented

GMP GUIDANCE / REFERENCE- WHO

PIC/S PE 009-14

Product Quality Review

A review of all significant deviations or non-conformances, their related investigations, and the effectiveness of resultant corrective and preventive actions taken

Quality Control

Records are made, manually and/or by recording instruments, which demonstrate that all the required sampling, inspecting and testing procedures were actually carried out. Any deviations are fully recorded and investigated

Production

Any deviation from instructions or procedures should be avoided as far as possible. If a

deviation occurs, it should be approved in writing by a competent person, with the involvement of the Quality Control department when appropriate

Annex 2

Pharmaceutical Quality System

Product and processes are monitored and the results taken into account in batch release, in the investigation of deviations and, with a view to taking preventive action to avoid potential deviations occurring in the future

Deviations, suspected product defects and other problems are reported, investigated and

recorded. An appropriate level of root cause analysis is applied during such investigations. The most likely root cause(s) should be identified and appropriate corrective actions and/or preventive actions (CAPAs) should be identified and taken. The effectiveness of CAPAs should be monitored.

Product Quality Review

Review of all significant deviations or non-conformances, the related investigations and the effectiveness of resultant CAPAs taken

Annex 2

GMP for Pharmaceutical Product

Records are made (manually and/or by recording instruments) during manufacture to show that all the steps required by the defined procedures and instructions have in fact been taken and that the quantity and quality of the product are as expected. Any significant deviations are fully recorded and investigated with the objective of determining the root cause and appropriate corrective and preventive action is implemented

Any planned changes or deviations in manufacturing or QC have been notified in accordance with a well-defined

reporting system before any product is released. Such changes may need notification to, and approval by, the

medicines regulatory authority

Good Practise in Production

Deviation from instructions or procedures should be avoided as far as possible. If deviations occur, they should be in accordance with an approved procedure. The authorization of the deviation should be approved in writing by a designated person, with the involvement of the QC department, when appropriate.

Annex 2

GMP for Pharmaceutical Product

Records are made (manually and/or by recording instruments) during manufacture to show that all the steps required by the defined procedures and instructions have in fact been taken and that the quantity and quality of the product are as expected. Any significant deviations are fully recorded and investigated with the objective of determining the root cause and appropriate corrective and preventive action is implemented

Any planned changes or deviations in manufacturing or QC have been notified in accordance with a well-defined

reporting system before any product is released. Such changes may need notification to, and approval by, the

medicines regulatory authority

Good Practise in Production

Deviation from instructions or procedures should be avoided as far as possible. If deviations occur, they should be in accordance with an approved procedure. The authorization of the deviation should be approved in writing by a designated person, with the involvement of the QC department, when appropriate.

PIC/S & WHO EXPECTATIONS

- Significant deviations are fully investigated

- Any deviations are fully recorded and investigated

- Assessment of deviations from specified procedures

- Incorporate risk assessment

- Reviewed in PQR

- Signed authorisation for deviation from manufacturing formula, processing instructions and packaging instructions

- Written policies, procedures, and the associated records of actions taken or conclusions reached of any deviations or non-conformances

- Any deviation from expected yield should be recorded and investigated

- Include stability program

SYSTEM DEVELOPMENT – DEVIATION HANDLING

Discrepancy Event: An event departure from GMP requirement during GMP task that requires assessment to determine one or more of the following: impact, cause, additional action, remediate action

DISCREPANCY MANAGEMENT PROCESS FLOW

DETECT

The purpose of the detect phase is to:

- Differentiate between process comment and deviation event

- Capture event detail

- Initiate discrepancy record

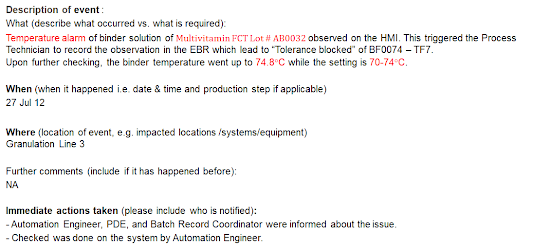

INFORMATION CONTENT – DETECT PHASE

INFORMATION CONTENT – EXAMPLE

PRELIMINARY IMPACT ASSESSMENT

Impact assessment must be:

- Scientifically justified

Data Driven

Use internal/external experts to determine impact (Chemists, Microbiologist, Validation, Regulatory Affairs, Engineering, Product Development, and Maintenance just to name a few). - Based on objective and realistic assessment

- In compliance with regulatory requirements and expectations

- Use a simple tools to assess the impact as per events criticality (low, medium & high impact)

- Know how the product is used by the end user/patient

- Process Comment: written explanation of unexpected of atypical event, observation, or clarification related to GMP tasks that do not required further assessment to determine cause or impact

- Deviation: a confirmed discrepancy event that requires documentation of one or more of the following: impact, cause, additional actions and technical assessment

- Investigation: a confirmed discrepancy event that has potential product quality impact that may affect patient safety risk and requires extensive testing or technical assessment to understand cause & impact and required remediate action

EXAMPLE PROCESS COMMENT

Verifiable documentation errors that are impacting approved specification or not requiring electronic data correction

- Minor cosmetic damage to primary or secondary material packaging with no impact to structural integrity

- Planned facility / equipment shutdown under approved procedural control

- Editorial Master Batch Records errors (e.g. typos)

- Acknowledgement of automation alarms where there is no intervention or where intervention is specified by an SOP

- Interruption of a step or production which does not conflict with the procedure or impact product quality

CLASSIFY

- The classification step requires quality to determine the criticality of the event

- Quality Assurance must decide if the deviation should be escalate to investigation

- Consult with the Head of Quality or Quality Review Board (QRB) as needed

DISCREPANCY CLASSIFICATION

CRITICAL DEVIATION

Deviation that could have significant impact on the product quality or GMP system and/or patient safety.

Example:

- Cross contamination or product mix up in a product

- Failure to process step during manufacturing

- Use of obsolete batch document / test method

- Filter integrity failure

MAJOR DEVIATION

Deviation that could have a moderate to considerable impact on the product quality or GMP system.

Example:

- Machine breakdown during processing

- Equipment out of calibration

- Wrong print batch number and expiry date on cartoon box

MINOR DEVIATION

Deviation unlikely to have a detectable impact on the product quality or GMP system

Example:

- Minor error in batch records or document that not affecting the integrity of data

- Spillage of material during dispensing

- Failure to meet environmental condition during batch processing

- Excursion alert limit of environmental monitoring result

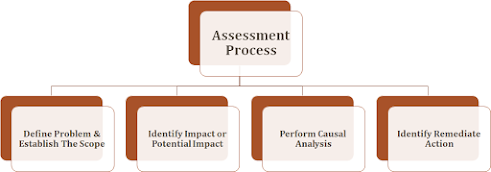

ASSESSMENT PROCESS

The purpose of the assessment process is to evaluate to the extend necessary, with the support from discrepancy owner and technical expert, for impact of the discrepancy event, identification action to mitigate effect of the event and reduce risk of recurrence and determine cause, and remediation actions

The assessment activities may vary depending on the nature of the discrepancy event and the conclusion of each assessment

ESTABLISHING SCOPE

IMPACT DETERMINATIONConduct assessment to ensure all relevant aspect of impact are identified and understood

Consider impact to:

- Validation status

- Regulation compliance

- Risk assessment and risk control

- Quality (e.g. safety, identity, purity or potency)

- Third party: licenses, partner, CMO, contract lab, contract warehouse, supplier / vendor

INVESTIGATION ASSESSMENT

When Deviation is escalate to an Investigation, additional assessment are performed to ensure:

- The level of risk: consider as new risk, impact to existing risk score

- Criticality: impact to product quality, safety, efficacy, regulatory compliance

- Partner impact

- Notification action a required: required notification to health authority if that event impact to distributed product

PREFORMING CAUSAL ANALYSIS

Identify the tools use to perform the analysis such as fishbone, 5-Why, Brainstroming

- Direct Cause

- Root cause (identify most probable cause when root cause is not definitive)

- Contributing Cause

Describe any key protocols, studies, additional testing that was performed to support causal analysis. Include the details of the effort and the results obtained

RECURRING DISCREPANCY ASSESSMENT

- Perform review of historical deviation and investigation data to find previous occurrences of the event for the same product/system/material

- To determine the scope of record to include in the analysis, consider opportunity for occurrence / detection

Review record data to determine event has occurred previously within the time period of the opportunity for occurrence / detection:

- If the status was the same

Status of existing remediation actions is warranted - If identification of new remediation action is warranted

- If additional remediation action are needed when previous implemented measures were found insufficient

RECURRING DISCREPANCY DATA STATUS

REMEDIATE ACTION

Remediate action are designed to:

CLOSURE

Comments

Post a Comment